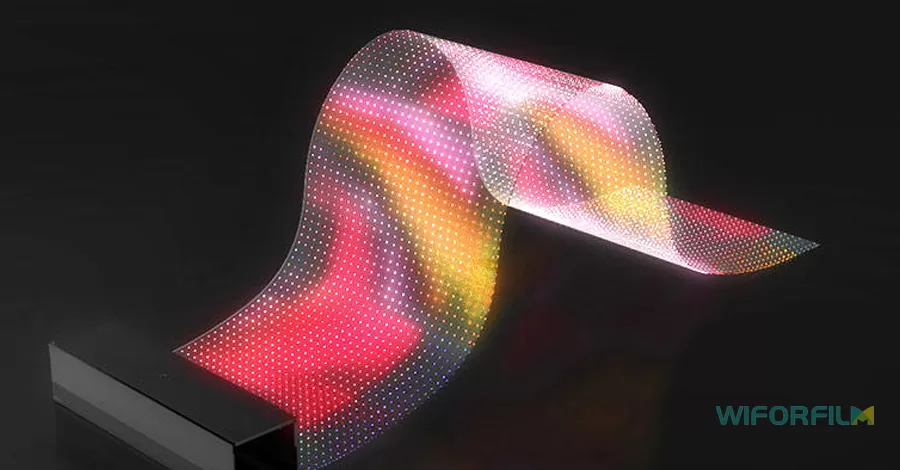

In the rapidly evolving world of display technology, flexible LED screen have redefined how we think about digital visuals on glass. These ultra-thin, bendable, and transparent displays allow architects, retailers, and designers to merge technology seamlessly with architecture — transforming ordinary glass surfaces into vivid digital canvases. But behind this innovation lies a critical process that makes it all possible: transparent adhesive bonding.

This bonding technique is more than just a way to attach the LED display to glass — it’s a sophisticated optical and structural enhancement process that improves performance, durability, and aesthetics. By eliminating the air gap between the display and the glass, transparent adhesive bonding creates a unified, high-clarity surface that looks stunning and lasts longer.

In this article, we’ll explore in detail how transparent adhesive bonding enhances flexible LED screen glass integration, focusing on optical, structural, and design improvements that elevate both performance and user experience.

1. Understanding Transparent Adhesive Bonding in LED Displays

At its core, transparent adhesive bonding—often called optical bonding—is the process of attaching a display module directly to a glass substrate using a clear adhesive layer. Unlike traditional mounting methods that leave a thin layer of air between the screen and glass, this technique fills the gap completely with a high-transmittance adhesive.

This adhesive, typically a silicone- or resin-based compound, serves several critical purposes:

- It eliminates the air gap, preventing internal reflections and glare.

- It enhances durability, shielding the display from dust, moisture, and impact.

- It improves optical clarity by matching refractive indices between the screen and glass.

In flexible LED screen applications—where displays need to conform to curved or irregular surfaces—transparent bonding is essential. It provides the structural integrity and elasticity required for stable adhesion without affecting flexibility.

2. Optical Enhancements: Clarity, Brightness, and Visual Comfort

Reduced Glare and ReflectionWhen there’s an air gap between the display and glass, light from external sources (like sunlight or indoor lighting) reflects off multiple surfaces. These reflections reduce screen visibility and create glare, making the image appear washed out.

Transparent adhesive bonding solves this problem by eliminating the air interface and matching the optical density between materials. The adhesive acts as a refractive bridge, minimizing reflection losses and enhancing contrast.

The result? A display that’s much easier to read — even under bright ambient light — making it ideal for outdoor signage, storefronts, and glass facades.

Increased Brightness and Light EfficiencyOptical bonding doesn’t just make the screen look clearer; it can also increase perceived brightness by around 10%. Because less light is lost to internal reflection, more of it passes through the glass, improving visibility without increasing power consumption.

This means a flexible LED screen can deliver the same vibrant image with lower energy use, helping reduce both heat generation and operational costs — a crucial advantage for large-scale installations that run continuously.

Higher Light Transmittance for True TransparencyModern transparent adhesives are engineered with exceptionally high light transmittance, often exceeding 98%, thanks to their optimized refractive index (typically around 1.41). This ensures that the LED screen maintains its transparency and visual fidelity, even when integrated directly onto glass.

In transparent LED applications — such as glass curtain walls or transparent advertising displays — maintaining this level of clarity is critical. Optical bonding ensures that the screen remains nearly invisible when off, preserving the natural aesthetics of the building while delivering brilliant, vivid imagery when powered on.

3. Structural and Durability Enhancements

Improved Protection Against Dust and MoistureFlexible LED screens, like any electronic device, are vulnerable to environmental factors. Dust, humidity, and moisture can gradually seep through unsealed gaps and damage the internal circuitry or LEDs.

Transparent adhesive bonding provides an airtight seal that prevents such contaminants from entering. By filling the void between the LED module and the glass, the adhesive acts as a protective barrier, extending the lifespan of the display and ensuring consistent performance over time.

This added protection is particularly beneficial for public installations, outdoor displays, and humid environments, where exposure risks are higher.

Enhanced Impact ResistanceOptical bonding doesn’t just improve optical quality — it strengthens the entire display structure. When the adhesive layer bonds the screen to the glass, it distributes mechanical stress more evenly across the surface.

Tests have shown that impact resistance can improve by around 20% compared to non-bonded systems. This makes the display less prone to cracking or delamination when exposed to vibrations, accidental knocks, or thermal expansion.

For applications in high-traffic areas, transportation hubs, or interactive installations, this added resilience is a key benefit.

Maintaining Flexibility on Curved or Bending SurfacesOne of the defining features of flexible LED screens is their ability to conform to curved or irregular glass surfaces — enabling creative architectural designs and futuristic display concepts.

Transparent adhesive bonding supports this flexibility through specialized elastic adhesives that maintain strong adhesion without becoming brittle. These adhesives can tolerate wide temperature variations and mechanical bending while keeping the bond intact.

This property allows manufacturers and designers to create seamless curved glass displays, transparent columns, or wraparound screens that merge elegantly with the environment — all without compromising performance.

4. Integration and Aesthetic Enhancements

Seamless Glass IntegrationTransparent adhesive bonding enables perfectly flush installation of flexible LED screens onto glass, without the need for bulky brackets or visible mounts.

The adhesive film adheres directly to the glass, creating a clean, frameless appearance. This not only saves space but also aligns with modern architectural preferences for minimalist, integrated design.

For retail stores, corporate buildings, and museums, this means digital displays can blend into glass walls, windows, or partitions — transforming them into dynamic, interactive surfaces that enhance rather than interrupt the space.

Slim and Unobtrusive DesignThe adhesive layer used in optical bonding is remarkably thin — sometimes just 50 micrometers (μm). This makes it ideal for applications where aesthetics and transparency are crucial.

By removing the need for a visible mounting system, bonded flexible LED screens achieve a sleek, unobtrusive look that complements the glass surface. When turned off, the display appears nearly invisible; when activated, it comes alive with vibrant, high-definition visuals.

This minimal thickness also reduces overall weight, simplifying installation and making maintenance easier.

Versatility in Design and IntegrationTransparent adhesive bonding allows for various integration styles, depending on design requirements. Whether the display is mounted behind the glass, embedded within laminated layers, or applied on the front surface, the adhesive adapts seamlessly.

Architects can use this flexibility to create:

- Frameless or borderless LED displays

- Dual-sided glass signage

- Transparent video walls integrated into facades

- Interactive smart glass applications

This versatility empowers designers to combine art, technology, and structure, giving them greater creative freedom while ensuring consistent performance.

5. Applications of Transparent Adhesive Bonding in Flexible LED Technology

The benefits of transparent adhesive bonding are reflected across a growing number of real-world applications:

- Retail Storefronts: Creating eye-catching, transparent digital displays that engage passersby without blocking the interior view.

- Architectural Glass Walls: Turning building facades into dynamic media surfaces while maintaining natural light transmission.

- Transportation Hubs: Durable, high-visibility signage for airports, train stations, and bus terminals.

- Museums and Galleries: Interactive transparent displays for exhibits that preserve visibility of the background.

- Corporate Spaces: Sleek, integrated digital branding on office partitions or meeting room glass.

Each of these applications relies on the seamless integration and enhanced optical performance made possible by transparent bonding.

Conclusion

Transparent adhesive bonding has revolutionized the integration of flexible LED screens with glass surfaces, bridging the gap between digital display and architecture.

By eliminating air gaps, it enhances optical clarity, reduces glare, and improves brightness — all while strengthening durability and flexibility. It allows designers to achieve slim, frameless, and highly aesthetic installations that merge seamlessly with their surroundings.

Associated Products

You may also be interested in the following products:

Self-Adhesive Transparent LED Display Film - P5

Transparent LED Film Display Screen - P6.25

Flexible LED Transparent Film Screen - P8

Ultra Transparent Film LED Screen

Transparent Flexible Film Screen - P15

LED Crystal Film Screen

Transparent LED Screen Film - P4